?

Wafer and Membrane Thickness, Warp, TTV

硅片和薄膜厚度��,彎曲���,TTV

Optical EchoProbe

光學(xué)反射探針

?

Outline概要

??? Introduction簡述

??? Measurement Requirements for Wafer Thinning硅片減薄測量要求

??? Discussion? of different approaches for Wafer Thickness Measurement硅片厚度檢測不同方法的討論

??? Optical? EchoProbe for Wafer Thickness Measurement光學(xué)反射探針的硅片厚度檢測

??? Applications應(yīng)用

?? –? Thickness and Warp after Grinding, Etching研磨,蝕刻后的厚度和翹曲

??– Measurement of stacks of non- and semiconducting materials (MEMS)

?? –半導(dǎo)體材料(MEMS)的堆疊檢測

??? Configurations結(jié)構(gòu)

??? Summary and Outlook總結(jié)和展望

?

Introduction介紹

History歷史

Supplies multiple technologies, for Thickness, global and local Filmstress,Sheet resistance and leakage current, EOT-CV, and adhesion, which are currently being used by the majority of semiconductor fabs and equipment vendors around the globe, including companies like Intel, HP, Freescale, AMD,IBM, TI, Philips, Hitachi, Fujitsu, NEC, Samsung, Hyundai, UMC, TSMC, CSM,Applied Materials, Novellus, among others.

提供多種檢測技術(shù)�����,檢測厚度�����,全部和局部薄膜應(yīng)力,薄膜電阻和滲漏電流�,EOT-CV和粘附力,現(xiàn)在大部分的半導(dǎo)體工廠和全球設(shè)備供應(yīng)商都在使用�,包括

Intel, HP, Freescale, AMD,? IBM, TI, Philips, Hitachi, Fujitsu, NEC,? Samsung, Hyundai,UMC, TSMC, CSM, Applied Materials, Novellus,和其它���。

??

Product Portfolio產(chǎn)品系列

●EOT – CV-IV measurements on gate oxide on product wafers硅片柵氧化層CV-IV測量

●RsL – non-contact sheet resistance and leakage current measurements非接觸式薄膜電阻和泄漏電流檢測

●4pp – 4 point probe for measuring thin metal films薄金屬薄膜檢測4點探針

●MC – metal contamination measurement金屬污染檢測

●Raman 360 – strain measurement應(yīng)變檢測

●128 – film stress measurement at room temperature室溫下薄膜應(yīng)力測量

●500 – film stress measurement at 500C 500度下薄膜應(yīng)力測量

●900 – film stress hysteresis and TDS at 900C (1,100 optional)900度(可選1100度)下磁滯和TDS薄膜應(yīng)力

●Aquaflex and Laminar – 4 point bend and MELT adhesion testers 4點彎曲和融化粘附性測試

●127 – surface flatness, local, die level and ultra low stress表面平整度�,局部��,拉模水平和超低應(yīng)力

●413 and UF800 – wafer thickness, surface roughness, warpage, trench height, bump size measurement (most people use it for insitu thickness monitoring during grinding)硅片厚度����,表面粗糙度����,翹曲,槽位高度����,凸起尺寸測量(很多把它用于研磨時原位厚度監(jiān)控)

?

?

Challenges of Ultra-Thin Wafers

?超薄硅片挑戰(zhàn)

? Method of Thinning

減薄方法

? Metrologyof Thin wafers

薄硅片度量

? Handling, mounting處理,裝配

? Shipping運輸

?

?

?

?

?

Most Common Measurement Techniques for Wafer Thickness Measurement

硅片厚度檢測的一般測量技術(shù)

?? Capacitance Methods電容方法

?? Drop Gauge滴落測量

?? Triangulation三角測量

? Low Coherence Interferometry

?? 低干擾干涉測量

?

Capacitance Probes Samples with Tapes 測量膠帶硅樣電容探針

?

?

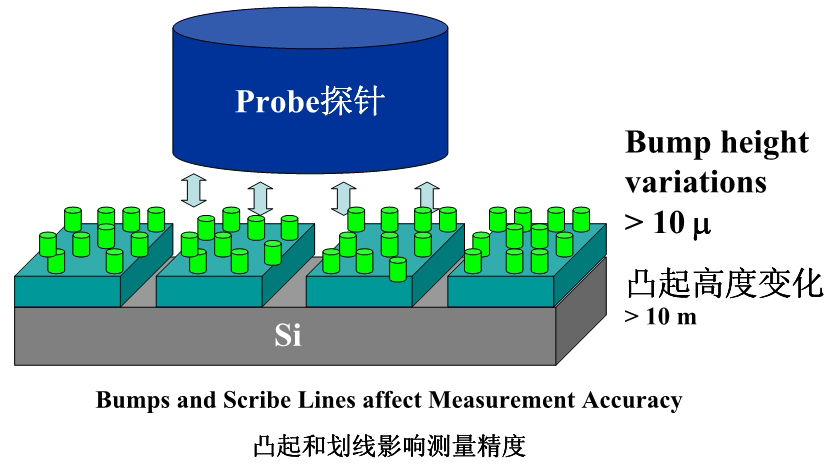

Capacitance Probes affected byBumped Wafers 凸起的硅片影響電容探針

?

?

Capacitance Probes電容探針

??? Accurate onlyfor bare wafers僅對裸片精確

??? Not accurate with patterned wafers對于圖案硅片不精確

??? Problematic for? wafers < 150 microns對硅片的不準(zhǔn)確度< 150微米

??? Not accurate for wafers with tapes對于帶膠帶的硅片不精確

??? Not accurate with bumped or diced wafers對于凸起的或者切塊的硅片不精確

??? Does not work with non-conducting materials不適用于不導(dǎo)電材料

?